Science

PhysicsX Secures $100 Million from Nvidia to Innovate Aerospace Manufacturing

PhysicsX, a startup focused on revolutionising part design for the aerospace and defence industries, has announced plans to raise up to $100 million from Nvidia, a global leader in semiconductor technology. The funding will support the company’s innovative platform, which accelerates component manufacturing by simulating material behaviours and engineering designs under various conditions. This advancement is set to transform the speed and cost structure of manufacturing in complex industries.

Nvidia’s investment comes on the heels of PhysicsX’s $20 million funding round in June 2023, following a successful $135 million Series B round earlier this year. Nvidia’s involvement underscores its growing interest in European startups that are developing technologies compatible with its hardware and software ecosystems. Furthermore, Nvidia retains the option to invest an additional $80 million in PhysicsX’s next funding round, signalling a long-term partnership. Nvidia CEO Jensen Huang has publicly committed to investing billions in UK-based startups, positioning PhysicsX as a key player in this strategy.

Transforming Manufacturing Efficiency

Founded in 2019 by former Formula 1 engineers Jacomo Corbo and Robin Tuluie, PhysicsX has gained recognition for its software’s ability to significantly reduce the need for physical prototypes. The platform’s advanced simulation engines enable manufacturers to rapidly iterate product designs, dramatically shortening development timelines and reducing costs. This capability is particularly appealing in sectors like defence and aerospace, where precision and reliability are essential, and the costs associated with trial and error can be substantial.

The technology also extends its applications beyond its primary markets, benefiting industries such as semiconductor fabrication, automotive, energy, and materials science. Noteworthy clients, including Rio Tinto, Siemens, and Applied Materials, leverage PhysicsX’s tools to enhance their innovation processes and improve product robustness.

Driving Innovation Through Simulation

PhysicsX’s platform addresses a fundamental challenge in manufacturing: understanding how parts will perform under real-world stresses without the need for costly physical testing. By utilising sophisticated computational models, the company offers engineers valuable insights that significantly reduce the trial-and-error phase of product development. This approach is crucial in high-stakes sectors like defence and aerospace, where product failures can have severe consequences.

The software not only accelerates product design cycles but also enhances confidence in the reliability of components. With its innovative technology and solid financial backing, PhysicsX is well-positioned to reshape manufacturing practices on a global scale, merging cutting-edge simulation with engineering expertise derived from high-performance racing backgrounds. As it continues to attract significant investment, PhysicsX aims to redefine the future of aerospace and defence manufacturing through advanced technology.

-

Health2 months ago

Health2 months agoNeurologist Warns Excessive Use of Supplements Can Harm Brain

-

Health2 months ago

Health2 months agoFiona Phillips’ Husband Shares Heartfelt Update on Her Alzheimer’s Journey

-

Science3 weeks ago

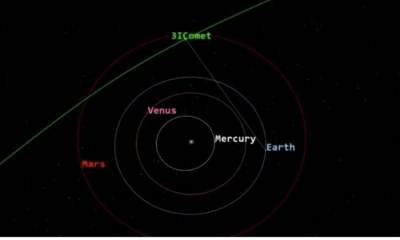

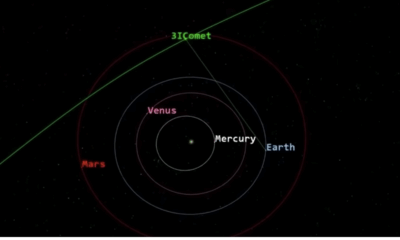

Science3 weeks agoBrian Cox Addresses Claims of Alien Probe in 3I/ATLAS Discovery

-

Science2 weeks ago

Science2 weeks agoNASA Investigates Unusual Comet 3I/ATLAS; New Findings Emerge

-

Science2 weeks ago

Science2 weeks agoScientists Examine 3I/ATLAS: Alien Artifact or Cosmic Oddity?

-

Science2 weeks ago

Science2 weeks agoNASA Investigates Speedy Object 3I/ATLAS, Sparking Speculation

-

Entertainment4 months ago

Entertainment4 months agoKerry Katona Discusses Future Baby Plans and Brian McFadden’s Wedding

-

World2 months ago

World2 months agoCole Palmer’s Cryptic Message to Kobbie Mainoo Following Loan Talks

-

Entertainment3 months ago

Entertainment3 months agoEmmerdale Faces Tension as Dylan and April’s Lives Hang in the Balance

-

Science2 weeks ago

Science2 weeks agoNASA Scientists Explore Origins of 3I/ATLAS, a Fast-Moving Visitor

-

Entertainment4 months ago

Entertainment4 months agoLove Island Star Toni Laite’s Mother Expresses Disappointment Over Coupling Decision

-

Entertainment3 months ago

Entertainment3 months agoMajor Cast Changes at Coronation Street: Exits and Returns in 2025