Business

Transform Warehouse Operations to Save $50K Monthly Now

Warehouse management issues are costing businesses up to $50,000 each month, leading to delayed shipments and significant inventory discrepancies. Many operations leaders are reporting that their current warehouse management systems, particularly implementations of SAP Extended Warehouse Management (SAP EWM), have failed to deliver on their promises. The consequences of these failures are severe, impacting supply chains, customer satisfaction, and overall profitability.

After collaborating with numerous supply chain directors across various industries, including manufacturing, pharmaceuticals, and retail, it has become evident that logistical challenges often stem from improper implementation of warehouse management systems. Many executives have expressed frustration, stating that their SAP EWM systems have not only underperformed but have also disrupted their operations.

Identifying the Root Causes of Warehouse Inefficiencies

Through extensive consultation and analysis, experts have pinpointed crucial breaking points within warehouse operations. Common issues include inadequate inventory management, lack of real-time data synchronization, and inefficient integration with existing systems. These problems can lead to substantial financial losses and eroded customer relationships.

For instance, a major pharmaceutical manufacturer faced a crisis after a $2.3 million investment in SAP EWM failed to yield expected results. Instead of relying on standard consulting practices, specialists utilized a tailored approach designed specifically for the unique challenges of warehouse operations in the United States. This methodology involves direct observation and analysis of day-to-day warehouse activities, focusing on every aspect from picking and packing to inventory audits.

Deliverables include a comprehensive diagnostic report that identifies precise areas where financial losses occur. Following this, the approach emphasizes redesigning operations, optimizing slotting strategies, and enhancing integration with other systems.

A Proven Transformation Blueprint

The transformation process consists of five key phases aimed at addressing the specific challenges faced by warehouse operations. The first phase involves thorough analysis and on-site observation to identify existing inefficiencies. Following this, experts redesign the warehouse operations, employing best practices and optimizing workflows.

An example of success comes from a national food and beverage distributor that implemented a similar strategy. After identifying influential “warehouse champions” within the organization, the team conducted over 200 hours of hands-on training. Within just 30 days, the adoption rate reached an impressive 95%.

Once the new system is implemented, rigorous testing and role-based training ensure that all personnel are prepared for the transition. Post-implementation support is crucial; teams often provide 24/7 assistance for the first 4-8 weeks to ensure a smooth transition.

Companies that have successfully navigated this transformation report significant improvements. For example, one client noted an increase in inventory accuracy from 81% to 99.4%, alongside a 40% increase in shipping volume without additional headcount.

The financial impact of these transformations is substantial. Typical returns on investment (ROI) can be realized within 12-18 months, with savings flowing directly to the bottom line. A mid-sized operation with an annual $150 million revenue reported a total annual impact of $13.1 million following a successful overhaul of their warehouse operations.

The results speak for themselves: reduced labor costs, improved inventory management, and enhanced customer retention. With these changes, businesses can expect better order fulfillment rates and the ability to meet customer demands more effectively.

In conclusion, the path to transforming chaotic warehouse operations into a streamlined, efficient system is clear. Businesses facing operational challenges have options. They can either continue to lose money and face customer dissatisfaction, or they can invest in proven strategies that turn their warehouses into competitive advantages. Companies like SCM Champs offer tailored solutions that not only address immediate challenges but also ensure sustained success in the long run.

-

Health2 months ago

Health2 months agoNeurologist Warns Excessive Use of Supplements Can Harm Brain

-

Health2 months ago

Health2 months agoFiona Phillips’ Husband Shares Heartfelt Update on Her Alzheimer’s Journey

-

Science3 weeks ago

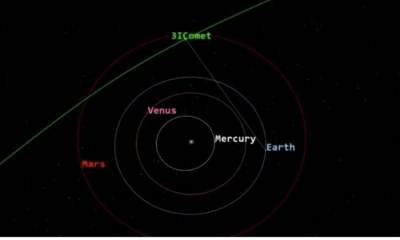

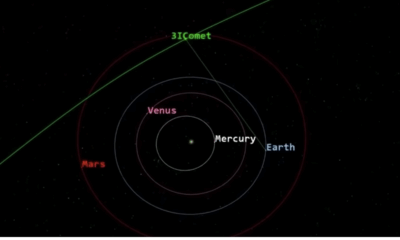

Science3 weeks agoBrian Cox Addresses Claims of Alien Probe in 3I/ATLAS Discovery

-

Science3 weeks ago

Science3 weeks agoNASA Investigates Unusual Comet 3I/ATLAS; New Findings Emerge

-

Science2 weeks ago

Science2 weeks agoScientists Examine 3I/ATLAS: Alien Artifact or Cosmic Oddity?

-

Science2 weeks ago

Science2 weeks agoNASA Investigates Speedy Object 3I/ATLAS, Sparking Speculation

-

Entertainment4 months ago

Entertainment4 months agoKerry Katona Discusses Future Baby Plans and Brian McFadden’s Wedding

-

World2 months ago

World2 months agoCole Palmer’s Cryptic Message to Kobbie Mainoo Following Loan Talks

-

Entertainment3 months ago

Entertainment3 months agoEmmerdale Faces Tension as Dylan and April’s Lives Hang in the Balance

-

Science2 weeks ago

Science2 weeks agoNASA Scientists Explore Origins of 3I/ATLAS, a Fast-Moving Visitor

-

Entertainment4 months ago

Entertainment4 months agoLove Island Star Toni Laite’s Mother Expresses Disappointment Over Coupling Decision

-

Entertainment3 months ago

Entertainment3 months agoMajor Cast Changes at Coronation Street: Exits and Returns in 2025