Science

Underwater Welding: Innovating the Future of Marine Infrastructure

Underwater welding is gaining recognition as a critical component of global infrastructure, providing essential maintenance and repair services for various industries. As teams of specialized divers operate beneath the surface of oceans, lakes, and harbors, they tackle vital tasks that ensure the functionality of oil rigs, ship hulls, and marine structures. This field combines human expertise with advanced technology, making it indispensable for sectors such as shipping and offshore energy.

Complex Challenges Beneath the Waves

Underwater welding involves a range of operations that are both technically demanding and physically strenuous. Skilled teams, composed of divers, engineers, and safety experts, work together to address urgent repair needs while also extending the lifespan of structures vulnerable to harsh marine environments. According to industry experts, the collaboration among these professionals is essential for refining techniques and ensuring safety.

Recent advancements in digital technologies, including 3D modeling and simulation, have transformed the way underwater projects are approached. These tools allow teams to test concepts before actual deployment, leading to safer and more accurate procedures. The integration of such technology has expanded the possibilities for repairs, ensuring that operations are not only effective but also efficient.

Innovation Driving Efficiency and Sustainability

The continuous evolution of equipment and methods plays a significant role in the advancement of underwater welding. Each project requires meticulous planning, as the ocean presents challenges such as unpredictable currents and visibility issues. Engineering design is critical in optimizing tools for underwater use, impacting precision and safety for divers.

Innovations in mechanical design have direct implications for operational success. Enhanced clamps, cutting tools, and remotely operated welding systems contribute to quicker project turnaround times and reduced downtime. This not only lowers costs for operators but also minimizes the environmental impact associated with marine work.

Looking ahead, the underwater welding industry is likely to see a blend of human skill and robotic assistance. While remote-operated vehicles and autonomous systems are being tested for hazardous tasks, human divers remain vital for their precision and adaptability. As companies innovate and push the boundaries of what is possible beneath the surface, underwater welding will continue to be a cornerstone of global infrastructure.

Although often overlooked, this specialized field is crucial for maintaining the seamless flow of goods and energy worldwide. By harnessing creativity, engineering, and practical experience, underwater welding exemplifies how innovation thrives in unexpected environments—deep below the waves.

-

Health3 months ago

Health3 months agoNeurologist Warns Excessive Use of Supplements Can Harm Brain

-

Health3 months ago

Health3 months agoFiona Phillips’ Husband Shares Heartfelt Update on Her Alzheimer’s Journey

-

Science2 months ago

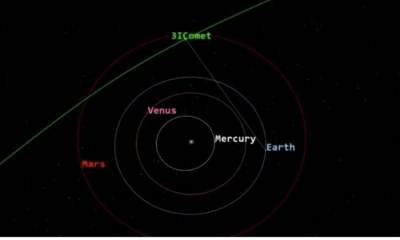

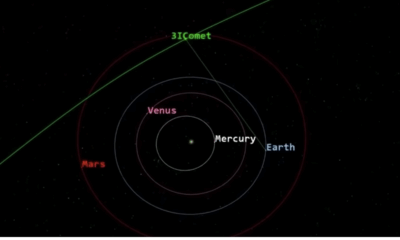

Science2 months agoBrian Cox Addresses Claims of Alien Probe in 3I/ATLAS Discovery

-

Science2 months ago

Science2 months agoNASA Investigates Unusual Comet 3I/ATLAS; New Findings Emerge

-

Science1 month ago

Science1 month agoScientists Examine 3I/ATLAS: Alien Artifact or Cosmic Oddity?

-

Entertainment5 months ago

Entertainment5 months agoKerry Katona Discusses Future Baby Plans and Brian McFadden’s Wedding

-

Science1 month ago

Science1 month agoNASA Investigates Speedy Object 3I/ATLAS, Sparking Speculation

-

Entertainment4 months ago

Entertainment4 months agoEmmerdale Faces Tension as Dylan and April’s Lives Hang in the Balance

-

World3 months ago

World3 months agoCole Palmer’s Cryptic Message to Kobbie Mainoo Following Loan Talks

-

Science1 month ago

Science1 month agoNASA Scientists Explore Origins of 3I/ATLAS, a Fast-Moving Visitor

-

Entertainment2 months ago

Entertainment2 months agoLewis Cope Addresses Accusations of Dance Training Advantage

-

Entertainment4 months ago

Entertainment4 months agoMajor Cast Changes at Coronation Street: Exits and Returns in 2025