Science

New Metamaterials Set to Revolutionize Vibration Protection

A groundbreaking development in vibration protection has emerged with the introduction of a new 3D-printed structure known as the kagome tube. This innovative design, created by researchers at the Wright-Patterson Air Force Base in Ohio, aims to safeguard sensitive equipment from damaging vibrations, particularly in civil and aerospace engineering applications.

The kagome tube is part of a category of materials called topological mechanical metamaterials. Unlike previous iterations, this design is straightforward enough for practical deployment in real-world situations. According to lead developer James McInerney, the structure’s unique attributes make it an effective shock absorber that could significantly enhance the durability of sensitive systems.

Innovative Design for Effective Vibration Isolation

The kagome tube’s design features a lattice of beams arranged to localize low-energy vibrational modes, known as floppy modes, to one side of the structure. This strategic arrangement allows vibrations that enter the system on the floppy side to remain contained, preventing energy from propagating to the other side. As McInerney explains, “This provides good properties for isolating vibrations because energy input into the system on the floppy side does not propagate to the other side.”

The lattice structure is based on a pattern originally proposed by the 19th-century physicist James Clerk Maxwell. By folding a flat Maxwell lattice into a cylindrical tube, the researchers created a self-supporting design. The kagome tube consists of a connected inner and outer layer, known as a kagome bilayer. Its radius can be precisely engineered to achieve the desired topological behavior.

Initial tests conducted by the research team involved attaching a virtual version of the kagome tube to a mechanically sensitive sample alongside a source of low-energy vibrations. The results confirmed that the tube effectively diverted vibrations away from the sensitive sample, demonstrating its potential for practical applications.

Future Applications and Research Directions

To further understand the tube’s geometry, the researchers developed a simple spring-and-mass model, treating it as a monolayer. This modeling suggested that the polarization of the tube should correspond with that of the monolayer. Additionally, the team incorporated rigid connectors at the tube’s ends and employed a finite-element method to analyze frequency-dependent vibration patterns throughout the structure.

The researchers are particularly focused on vibration-isolation applications that require a passive support structure. These applications are especially relevant in scenarios where the performance of existing passive mechanisms, such as viscoelastomers, is compromised by temperature limitations. McInerney states, “Our tubes do not necessarily need to replace other vibration isolation mechanisms. Rather, they can enhance the capabilities of these by having the load-bearing structure assist with isolation.”

As the research progresses, the team’s primary objective will be to explore the implications of physically mounting the kagome tube on vibration isolation structures. McInerney highlights the importance of this next step: “The numerical study in our paper uses idealized mounting conditions so that the input and output are perfectly in phase with the tube vibrations. Accounting for the potential impedance mismatch between the mounts and the tube will enable us to experimentally validate our work and provide realistic design scenarios.”

In summary, the development of the kagome tube by McInerney and his colleagues represents a significant advancement in the field of vibration protection. This innovative structure could enhance the resilience of sensitive equipment, paving the way for safer and more reliable applications in various engineering domains. The findings are detailed in the journal Physical Review Applied, marking a promising step forward in materials science and engineering.

-

Health3 months ago

Health3 months agoNeurologist Warns Excessive Use of Supplements Can Harm Brain

-

Health3 months ago

Health3 months agoFiona Phillips’ Husband Shares Heartfelt Update on Her Alzheimer’s Journey

-

Science1 month ago

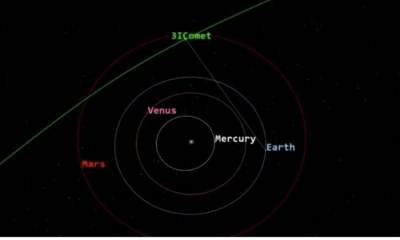

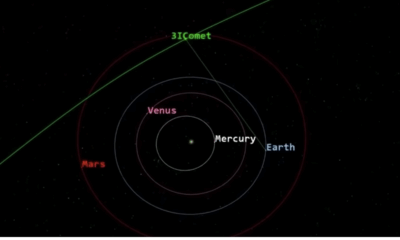

Science1 month agoBrian Cox Addresses Claims of Alien Probe in 3I/ATLAS Discovery

-

Science1 month ago

Science1 month agoNASA Investigates Unusual Comet 3I/ATLAS; New Findings Emerge

-

Science4 weeks ago

Science4 weeks agoScientists Examine 3I/ATLAS: Alien Artifact or Cosmic Oddity?

-

Science4 weeks ago

Science4 weeks agoNASA Investigates Speedy Object 3I/ATLAS, Sparking Speculation

-

Entertainment4 months ago

Entertainment4 months agoKerry Katona Discusses Future Baby Plans and Brian McFadden’s Wedding

-

Entertainment4 months ago

Entertainment4 months agoEmmerdale Faces Tension as Dylan and April’s Lives Hang in the Balance

-

World3 months ago

World3 months agoCole Palmer’s Cryptic Message to Kobbie Mainoo Following Loan Talks

-

Science4 weeks ago

Science4 weeks agoNASA Scientists Explore Origins of 3I/ATLAS, a Fast-Moving Visitor

-

Entertainment4 months ago

Entertainment4 months agoLove Island Star Toni Laite’s Mother Expresses Disappointment Over Coupling Decision

-

Entertainment3 months ago

Entertainment3 months agoMajor Cast Changes at Coronation Street: Exits and Returns in 2025